Maximizing Garage Door Hinge Lifespan

Published: Jan 28, 2026

Is your garage door trying to tell you something? Those squeaks, groans, and stutters aren't just annoying noises—they're often cries for help from one of the hardest-working parts of the system: the hinges.

Think of your garage door hinges as the joints in your body. They are the critical connection points that allow the heavy door panels to bend and glide smoothly along the track. When they're healthy, you barely notice them. But when they start to fail, the entire system can become noisy, unsafe, and prone to costly damage.

This guide is your go-to resource for decoding your door's language. We'll walk you through everything from basic hinge anatomy to a simple "symptom checker" that will help you decide when to maintain and when it's time to replace.

Foundation: The Anatomy of a Garage Door Hinge

What Do Garage Door Hinges Actually Do?

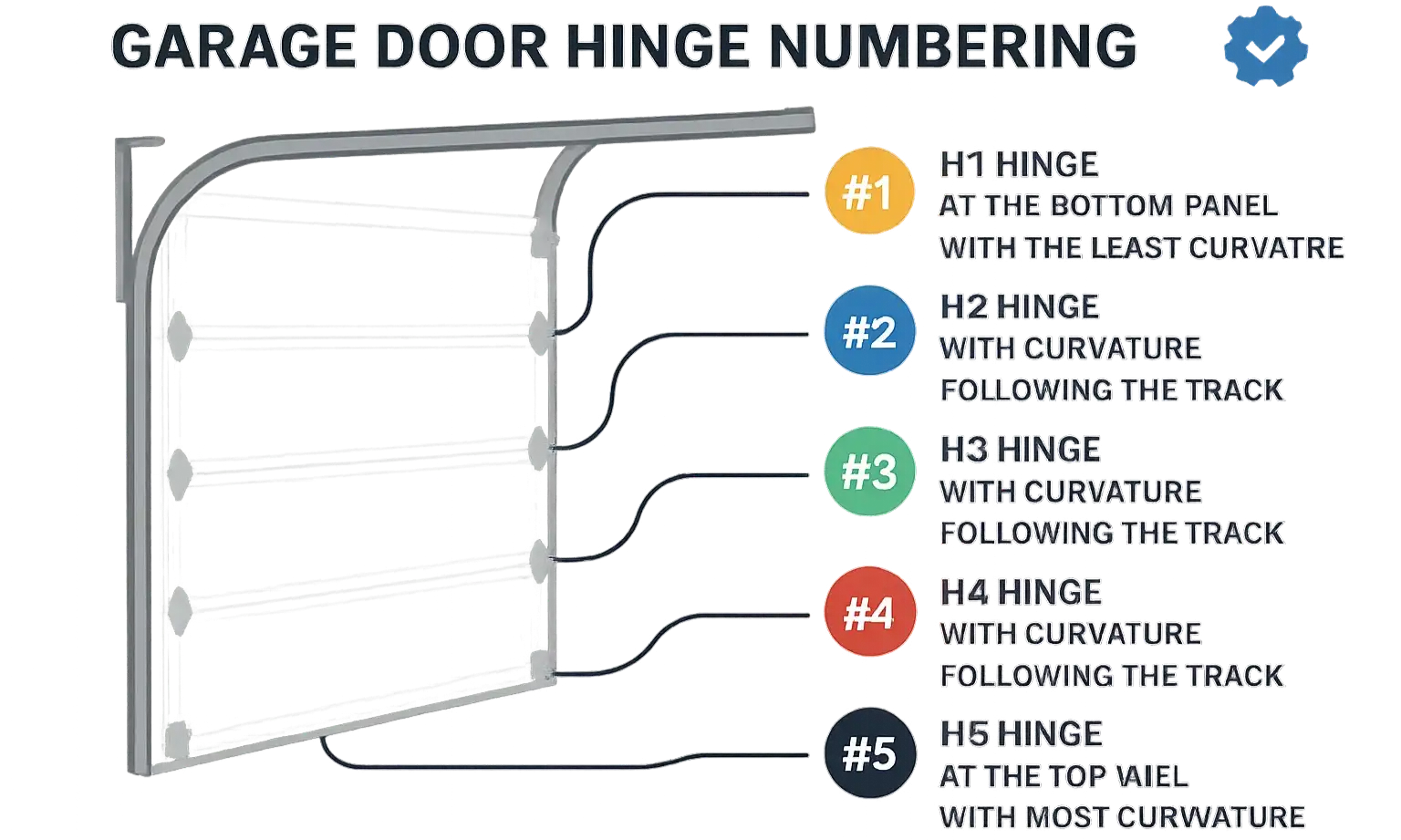

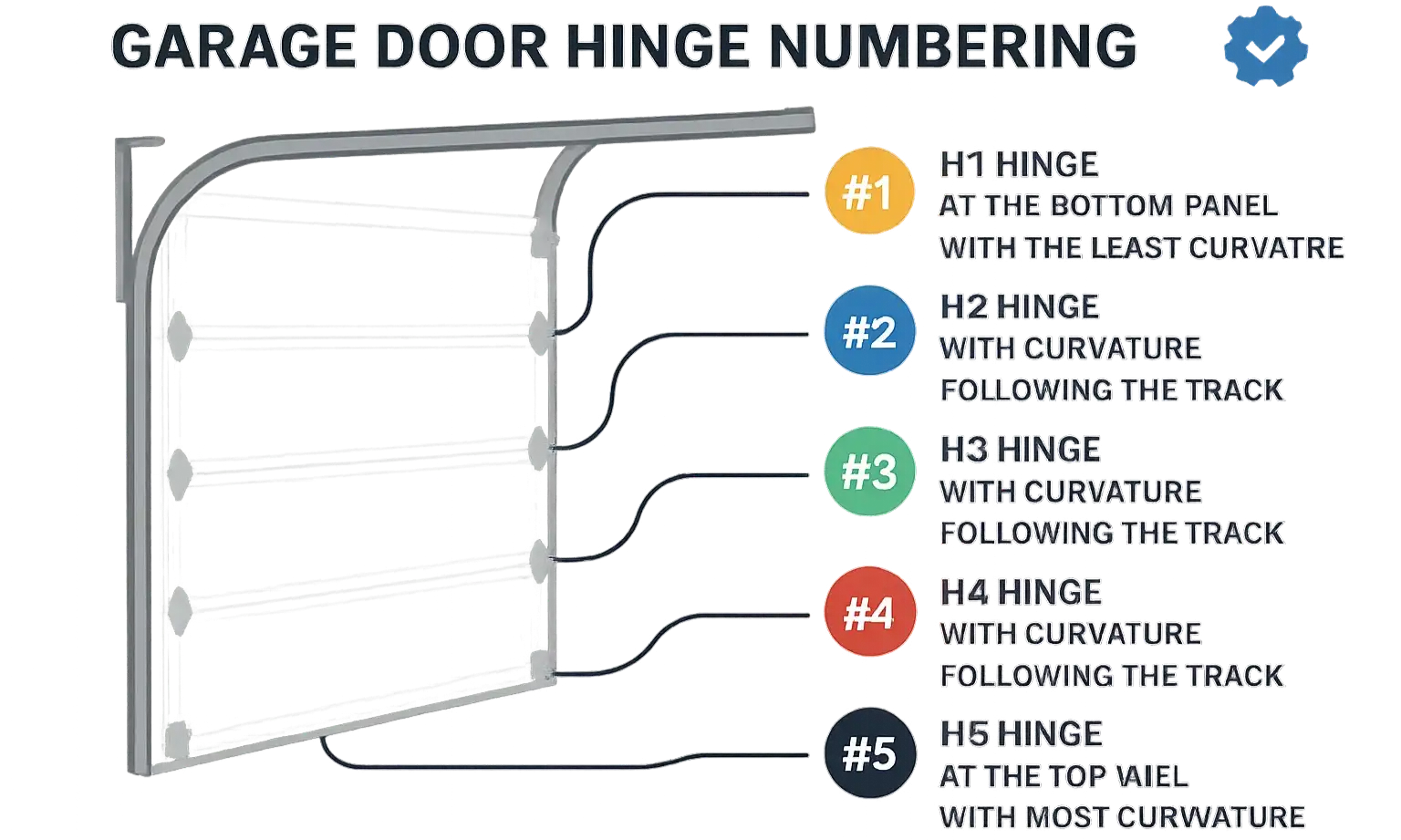

The Hinge Numbering System Explained: Your First "Aha" Moment

- #1 Hinges: These are the most common and are used in the center of the door to connect all the panels. They hold the rollers closest to the door.

- #2, #3, #4 Hinges (and up): These are placed on the outer edges of the panels, starting from the bottom. A #2 hinge places the roller slightly further out than a #1, a #3 slightly further than a #2, and so on. This graduated spacing ensures the door follows the track's curve without binding.

Hinge Materials and Gauge: What Durability Looks Like

- 14-Gauge: This is the standard for most residential doors. It's perfectly adequate for typical use.

- 11-Gauge: This is a thicker, heavy-duty option. If you have an oversized, heavy, or insulated door, 11-gauge hinges provide superior strength and a longer lifespan.

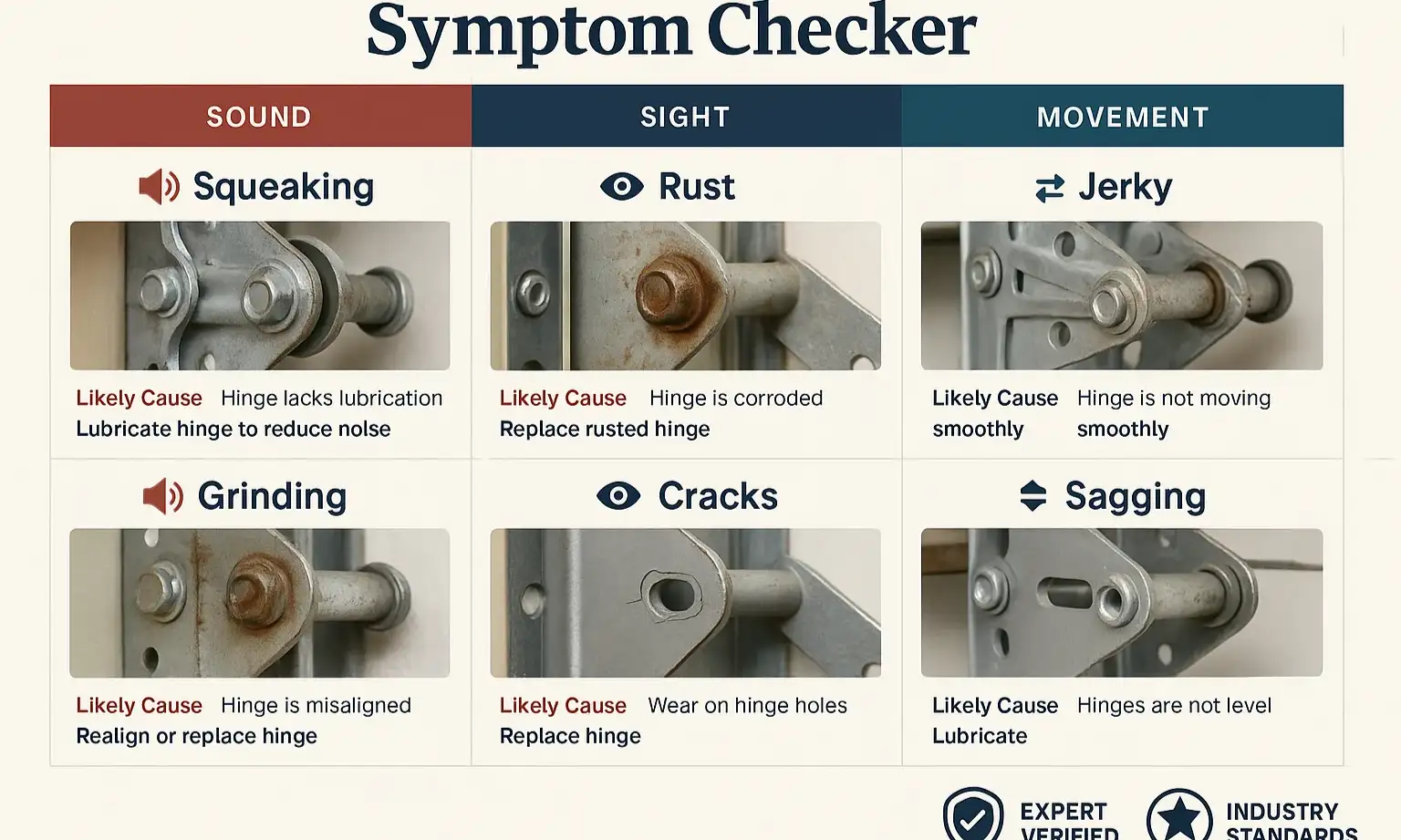

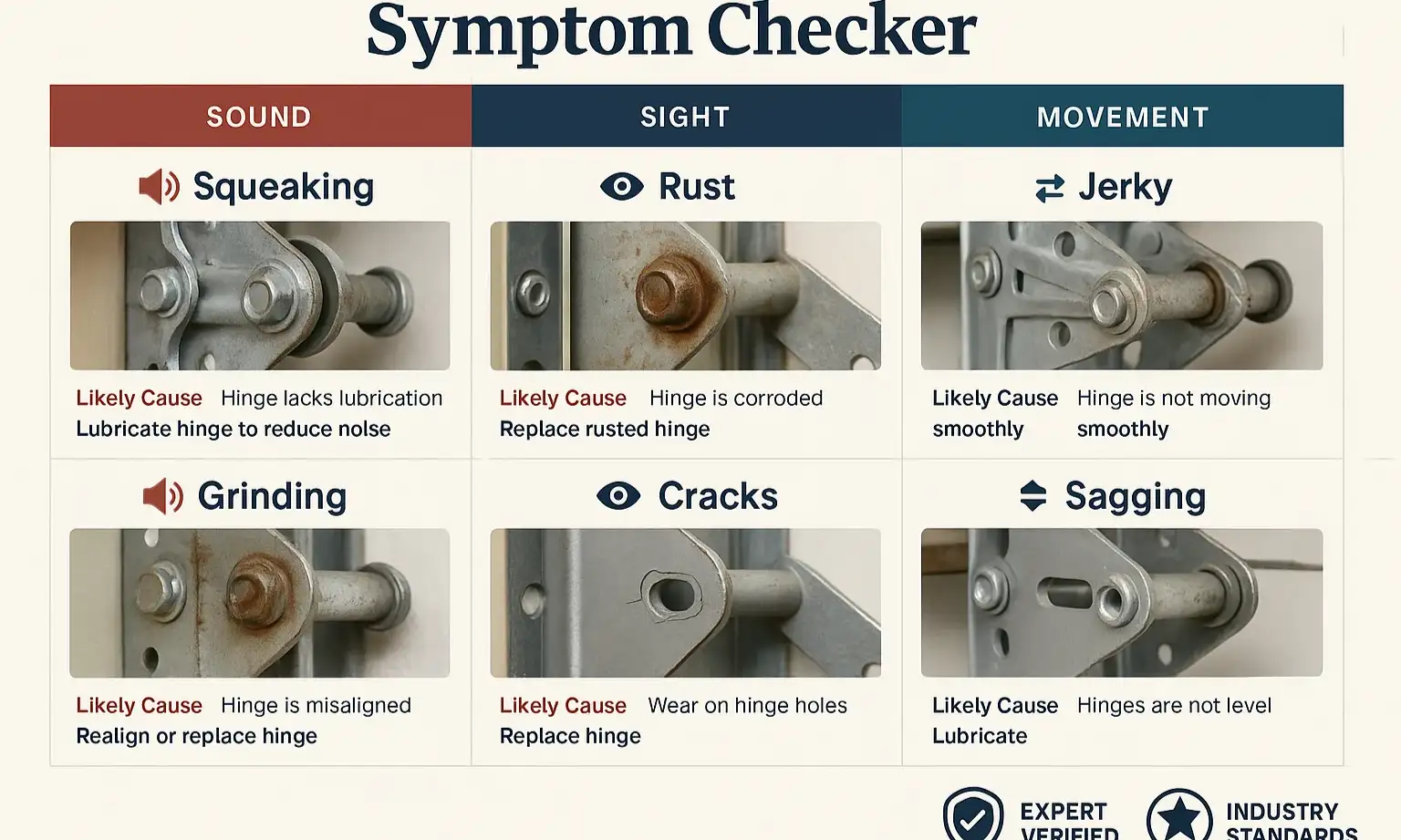

Building: The Maintain vs. Replace Decision Framework (The Symptom Checker)

Listen: Decoding Your Garage Door's Language

- Squeaking or Squealing: This is the sound of dry metal rubbing against metal. It's the earliest sign that your hinges are thirsty for lubrication.

- Grinding: A harsher, grittier sound than a squeak. This often indicates that dirt and debris have mixed with old lubricant, or that rust is creating friction. This is a sign that replacement might be on the horizon.

- Popping or Snapping: This is an urgent sound. It can mean a hinge is so loose that it's shifting under pressure, or worse, that the metal has cracked and is about to fail completely. If you hear this, a thorough visual inspection is critical. A loud door can have many causes, but finding a reliable noisy garage door fix starts with identifying the source.

Look: Visual Clues of Hinge Distress

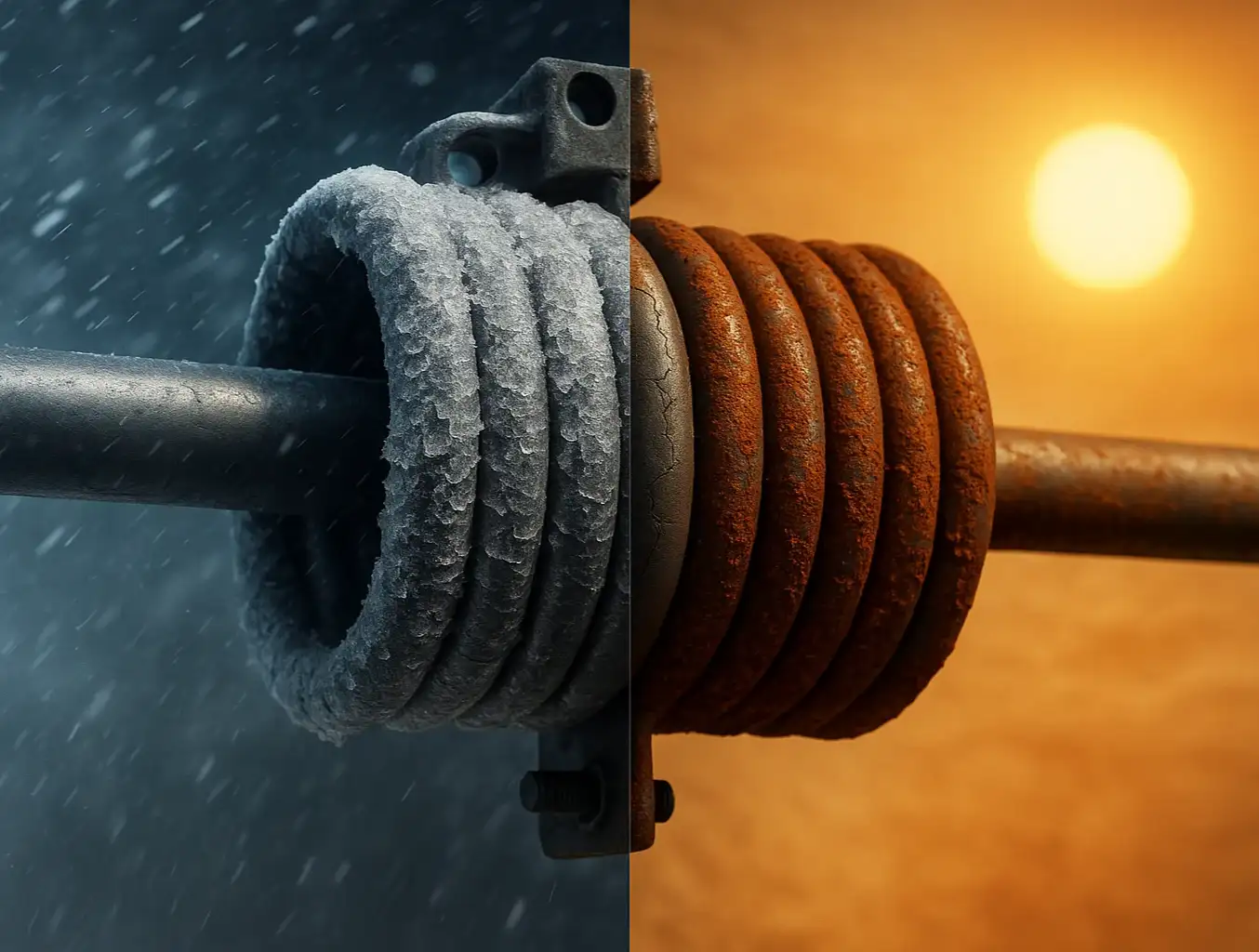

- Visible Rust: Surface rust can often be cleaned, but deep, flaking rust is a sign that the metal's integrity is compromised. If you're figuring out how to repair a rusted garage door panel, don't forget to check the hinges—they often rust first.

- Cracks or Stress Fractures: Look closely around the screw holes and the pivot point. Any visible crack, no matter how small, means the hinge is failing and must be replaced immediately.

- Elongated Screw Holes: If the holes where the screws attach the hinge to the door look oval instead of round, it means the hinge has been shifting under stress. This can cause the door to sag and should be addressed promptly.

Feel: When the Movement is Wrong

- Jerky or Stuttering Motion: If the door seems to catch or hesitate as it moves, it's often due to worn-out hinges binding instead of pivoting smoothly.

- Sagging or Uneven Gaps: Look at the gaps between the door panels. If they appear uneven or one side of the door hangs lower than the other, failing hinges could be the culprit, as they are no longer holding the panels in proper alignment.

Mastery: Taking Action

How to Properly Lubricate Your Hinges (The Right Way)

- Wipe Down: Use a rag to wipe away any dirt, dust, and old, gunky lubricant from the hinge and its pivot point.

- Choose the Right Lubricant: This is critical. Use a garage door-specific lubricant, which is typically a silicone or white lithium grease spray.

- Apply Sparingly: Spray a small amount directly into the hinge's pivot point. You don't need to coat the entire hinge.

- Work it In: Operate the garage door a few times to allow the lubricant to penetrate deep into the joint.

- Wipe Excess: Use a clean rag to wipe away any excess lubricant, which can attract dust and dirt.

When to Replace a Hinge: The Point of No Return

- Any cracks or fractures in the metal.

- Deep, structural rust that compromises the hinge's strength.

- A hinge that is noticeably bent or warped.

- Severely elongated screw holes that prevent a secure fit.

Need more information?

Get a free quote

Action: Your Long-Term Hinge Health Plan

- Every 6 Months (Spring & Fall): Perform a full "Symptom Check." Listen, look, and feel for any of the warning signs listed above.

- Lubricate: As part of your six-month check, apply the proper lubricant to all hinge pivot points.

- Tighten Hardware: Gently check if any hinge screws have become loose and tighten them as needed. Be careful not to overtighten.

Frequently Asked Questions (FAQ)

Why are garage door hinges numbered?

What is the best lubricant for garage door hinges?

Can I replace just one broken hinge?

Is replacing a garage door hinge a DIY job?

You may also like