Fixing Rust on Garage Door Tracks and Rollers

Published: Jan 23, 2026

Ever been jolted by a sudden grinding, squeaking, or shuddering noise as your garage door opens or closes? It’s a sound that makes you cringe, and for good reason. That noise isn't just an annoyance; it's a warning sign. Your garage door is trying to tell you something important about its health, and often, the culprit is a small, creeping problem you might not have noticed: rust.

Many homeowners see a bit of rust on their garage door tracks or rollers and dismiss it as a cosmetic issue. But that reddish-brown coating is a performance killer. It creates friction, forcing your entire system to work harder and leading to bigger, more expensive problems down the line. The good news? You can often tackle this problem yourself. Understanding what's happening and why it matters is the first step toward a smoother, quieter, and longer-lasting garage door system. If you're looking for a more general guide to a noisy garage door fix, we have you covered, but here we’ll focus specifically on the damage caused by rust.

Foundation: The 'Why' Before the 'How'

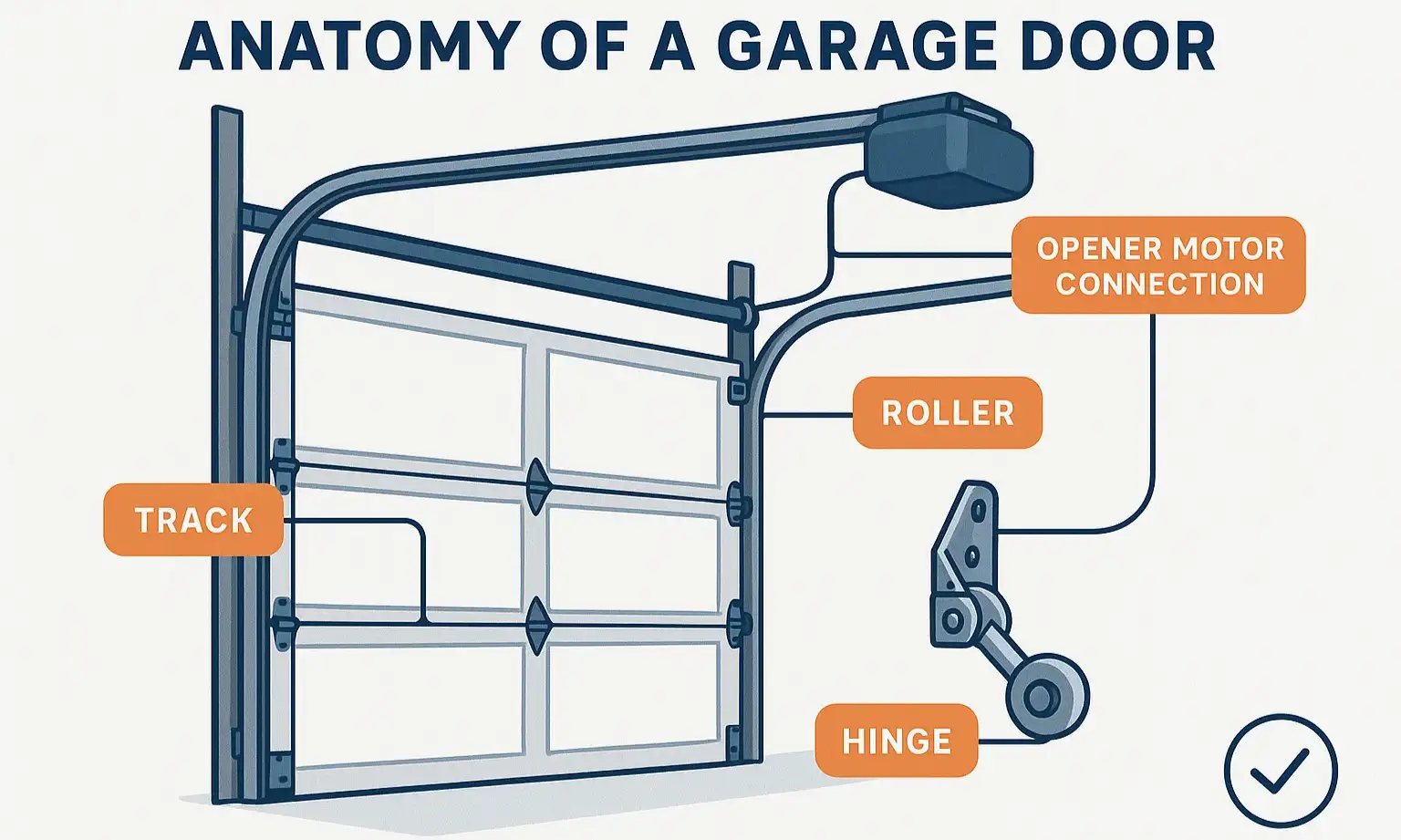

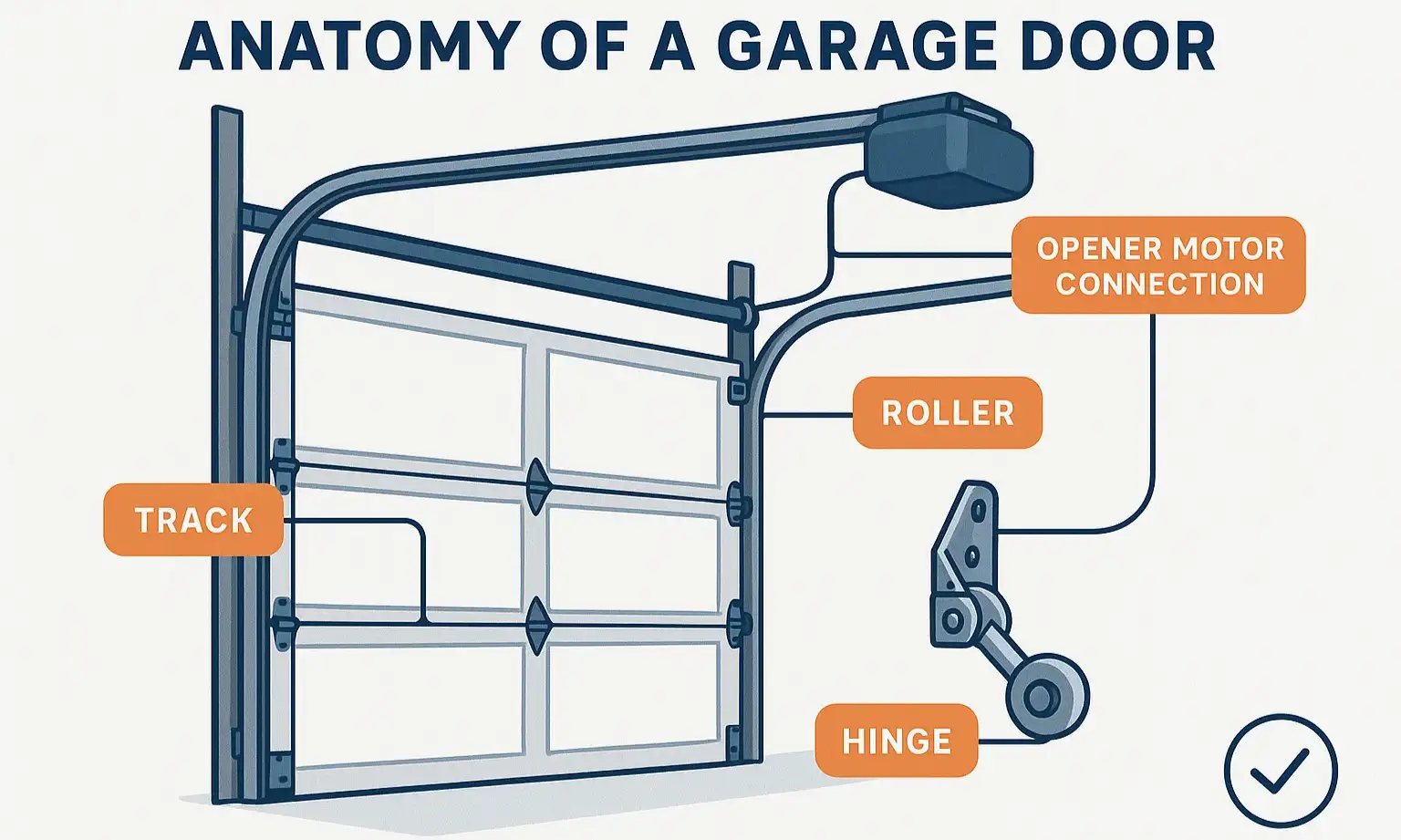

Anatomy 101: A simple, annotated diagram of the track, rollers, and hinges

The Vicious Cycle: How Rust Hijacks Your Garage Door's Performance

- Friction is Born: Rust isn’t smooth. Its abrasive surface creates immense friction, forcing the rollers to scrape and drag instead of glide.

- The System Strains: Your garage door opener is designed to lift a specific, balanced weight. When it has to fight against friction, it puts a heavy strain on the motor, gears, and chain or belt.

- Damage Spreads: This constant strain can lead to premature wear on the opener, damage to the rollers themselves, and can even throw off the alignment of your door. That initial grinding sound evolves into jerky movements, a door that struggles to open, or one that stops entirely.

Building: The Step-by-Step Fix (The 'How')

Safety First & Tools You'll Need

- Sturdy ladder

- Gloves and safety glasses

- Bucket of warm water and a few drops of dish soap

- Several clean cloths or rags

- Wire brush or steel wool

- White vinegar in a spray bottle

- A high-quality, garage-door-specific lubricant (lithium or silicone-based)

Step 1: The Clean-Up

Step 2: Rust Removal

- Spray the white vinegar directly onto the rusted areas of the track.

- Let it sit for 5-10 minutes. The acetic acid will help break down the rust.

- Use your wire brush or steel wool to scrub the rust away. Work in small sections.

- Wipe the track clean with a fresh, dry cloth to remove all rust particles and vinegar residue.

Step 3: Lubrication - The Right Way

- Target the Rollers: Lightly spray the lubricant on the stems of the rollers where they connect to the hinges.

- Lubricate the Hinges: Apply a small amount of spray to all the door's hinges.

- Work it In: After applying the lubricant, manually open and close the door a few times to distribute it evenly and work it into the moving parts.

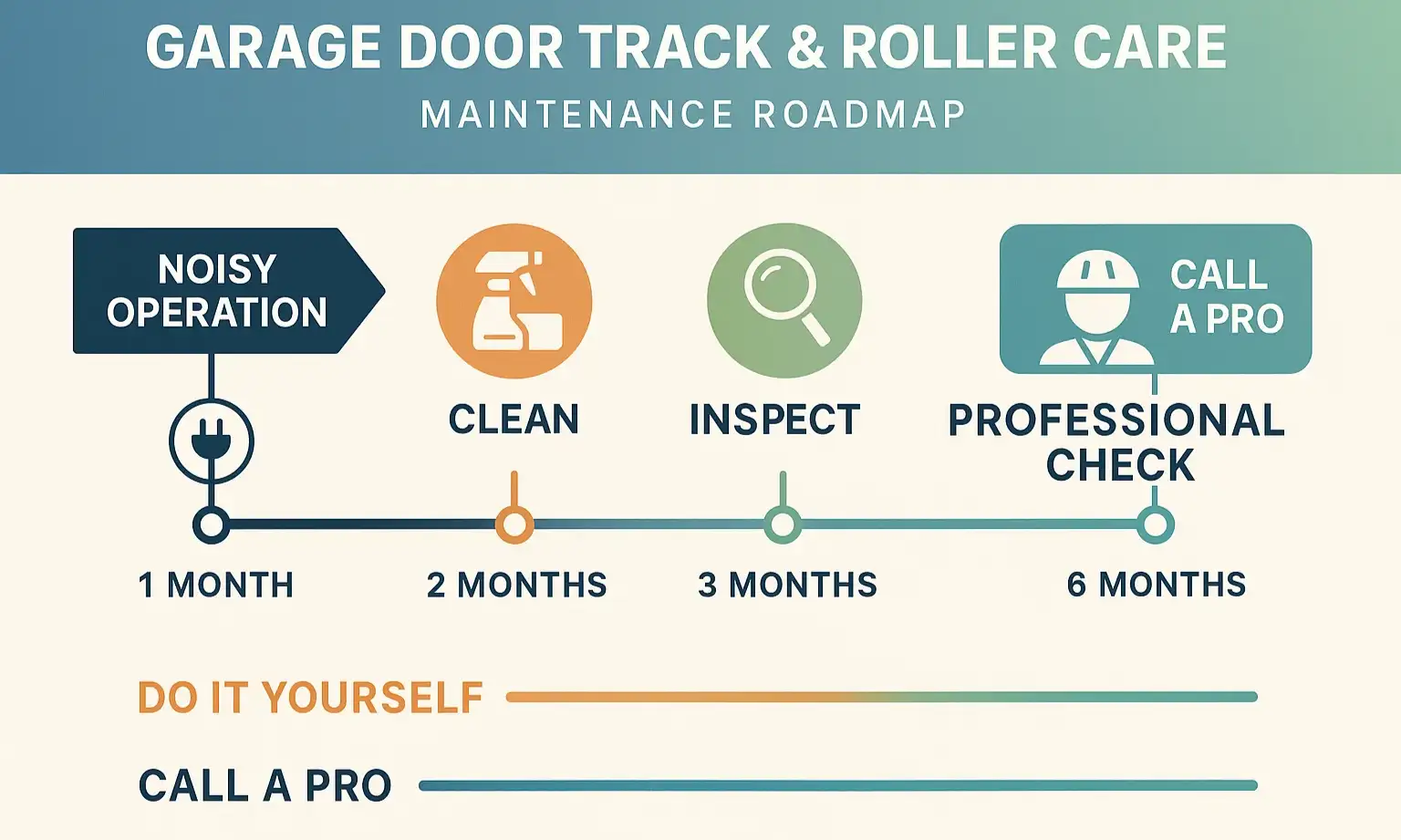

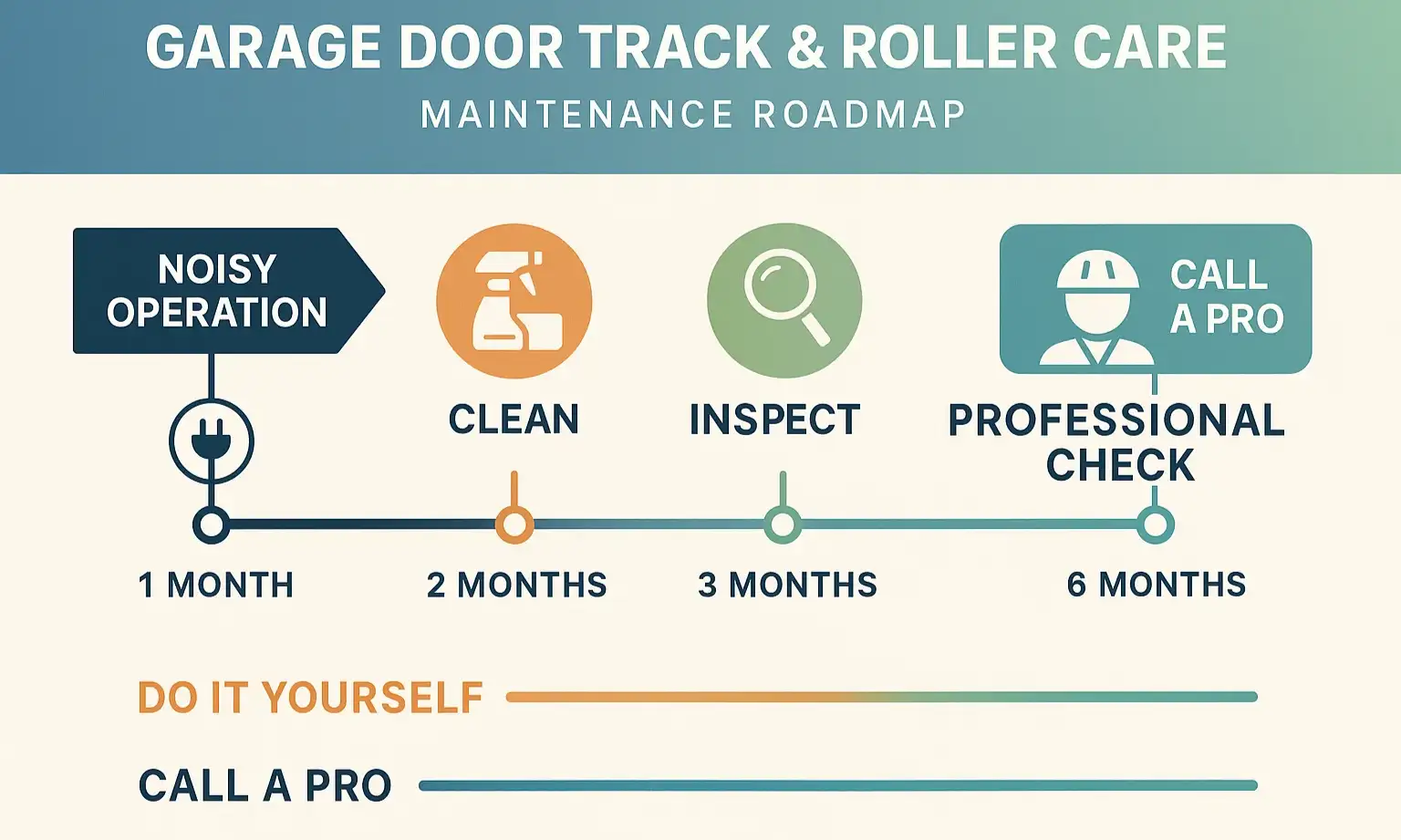

Mastery: Prevention and When to Call a Pro

- Bent or Damaged Tracks: If a track is dented or bent, no amount of cleaning will fix it. Trying to bend it back yourself can cause serious alignment issues. A professional will need to handle the garage door track installation correctly.

- Deep, Flaking Rust: If the metal is corroded and brittle, the structural integrity is compromised.

- Worn or Broken Rollers: If your rollers are cracked, wobbly, or seized up, they need to be replaced. A technician can help you choose and safely replace garage door rollers.

Need more information?

Get a free quote

Frequently Asked Questions (FAQ)

How often should I clean and lubricate my garage door tracks?

Can I just spray lubricant on the rust without cleaning it first?

What's the difference between steel and nylon rollers?

My rust seems to be on the door panels, not the tracks. What should I do?

A Smooth Finish

You may also like