Steel vs. Nylon Garage Door Rollers: The Ultimate Guide to Lifespan

Published: Jan 14, 2026

Ever stood in your driveway and winced as your garage door screeched its way open? That grating, metal-on-metal sound is a common complaint, and most people assume the solution is a simple choice: switch from steel to nylon rollers.

While that's part of the story, it's like choosing a car based only on its color. The real secret to a quiet, long-lasting, and smooth-operating garage door isn't just about steel versus nylon. It’s about understanding a simple but powerful performance equation.

Hook: It's Not Just About Steel vs. Nylon.

The biggest "aha moment" in understanding garage door rollers is realizing that the wheel's material is only one piece of the puzzle. True performance and longevity come from a combination of factors.

More Than a Wheel: The Anatomy of a Garage Door Roller

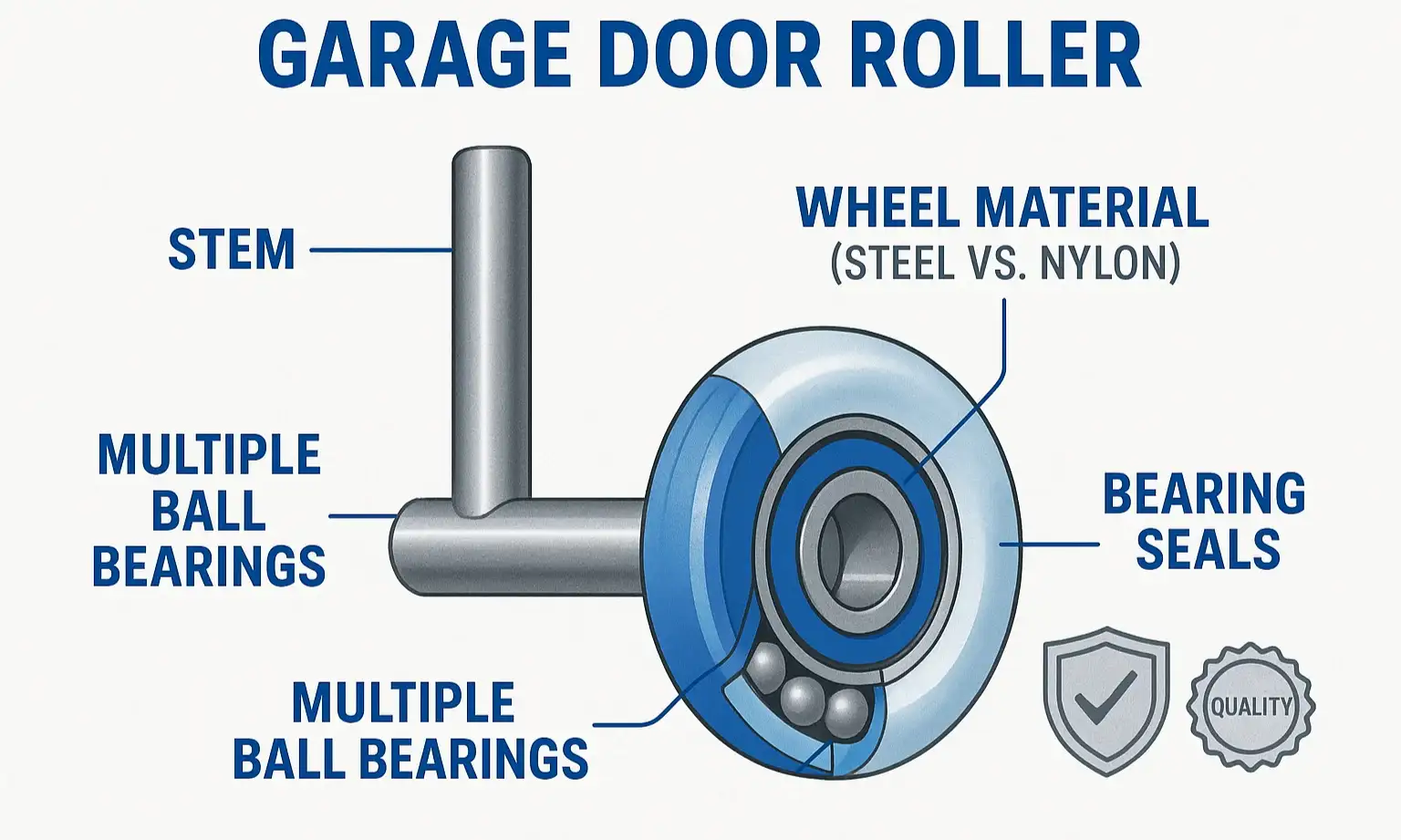

Before we can compare, let's quickly break down the components. A garage door roller isn't just a wheel; it's a small, hard-working assembly. Understanding the parts of a garage door like rollers is the first step to proper maintenance.

Foundation: Anatomy of a Garage Door Roller

- Stem: The metal shaft that slots into the hinges on the side of your garage door.

- Wheel: The part that rolls within the track. This is where the steel vs. nylon debate comes from.

- Ball Bearings: Tiny steel balls housed inside the wheel that allow it to spin smoothly around the stem. This is the single most important component for noise reduction and lifespan. Some cheap rollers have no bearings at all.

- Seals (or Lack Thereof): High-quality rollers have sealed bearings. This protective casing keeps dust, debris, and moisture out while keeping lubrication in, dramatically extending the roller's life. Unsealed bearings are exposed to the elements.

Now that you know the anatomy, let's see how these components come together in the real world.

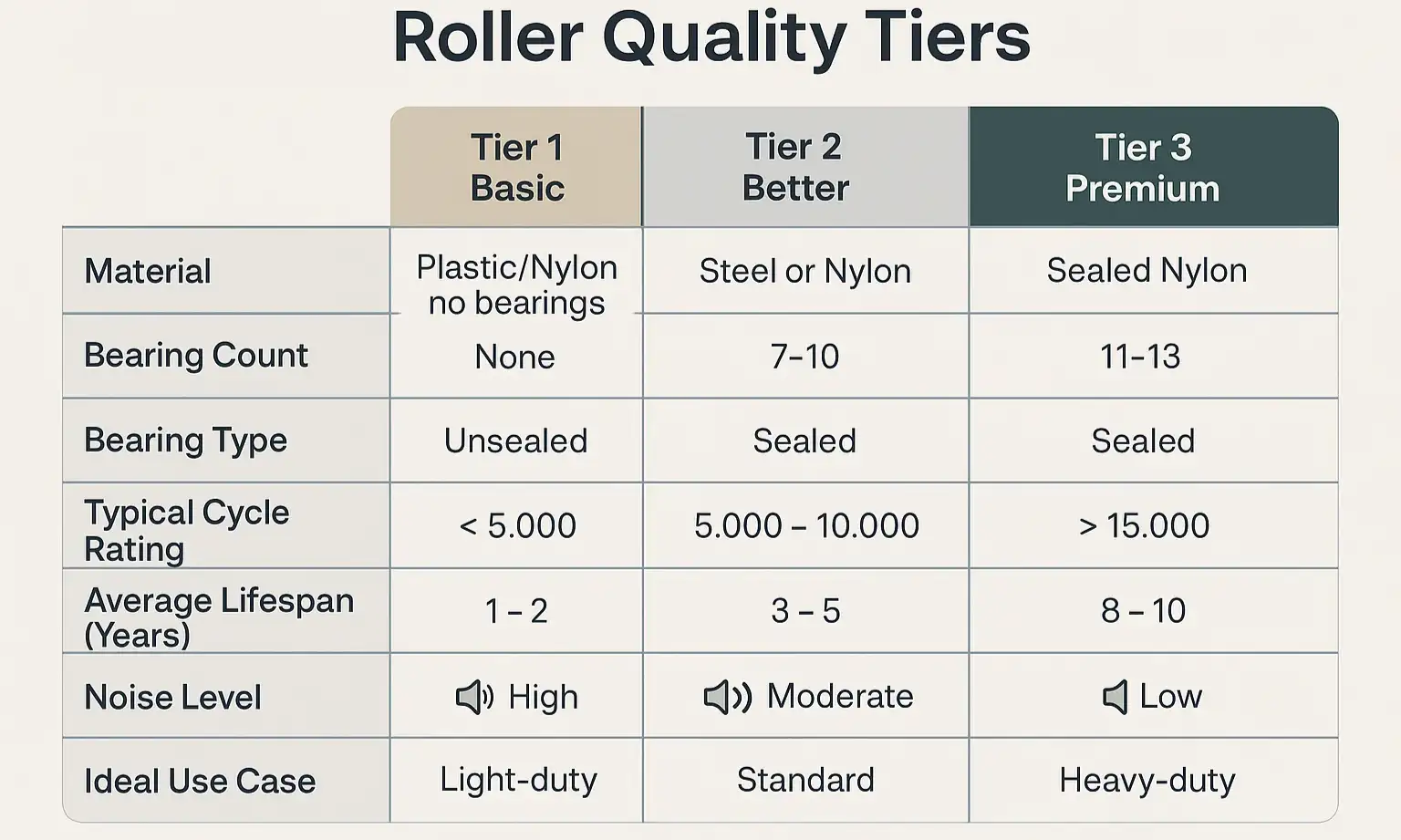

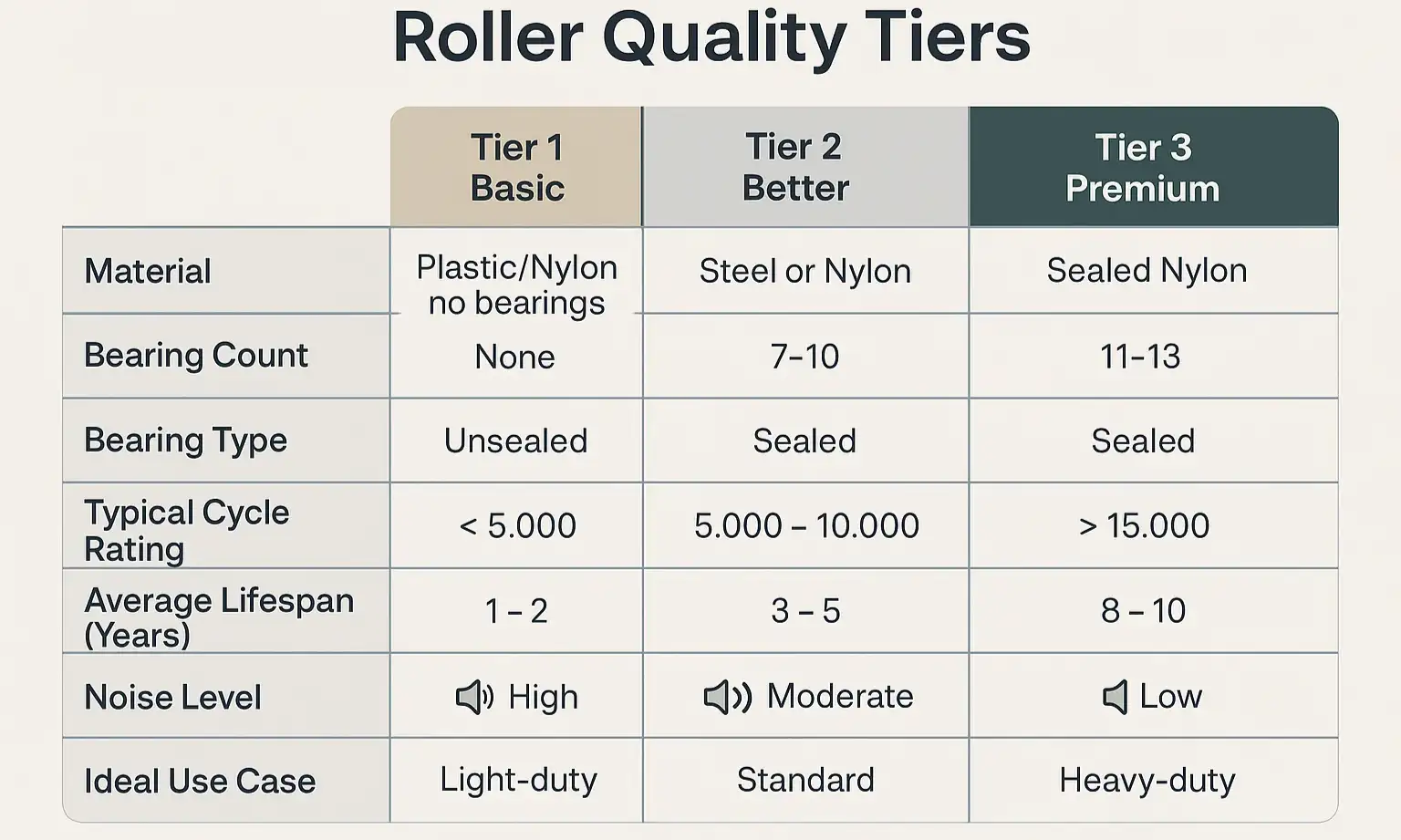

The Three Tiers of Garage Door Rollers

Instead of a simple "steel vs. nylon" showdown, it's more helpful to think of rollers in three quality tiers. This tiered system helps clarify why some "nylon" rollers fail in a year while others last for fifteen.

Tier 1: Basic Rollers (The Contractor Grade)

- Materials: Plastic or steel wheels with no ball bearings.

- Lifespan: 1-3 years (approx. 1,000-2,000 cycles).

- Description: These are the most basic, inexpensive rollers often installed on new construction homes. The wheel grinds directly on the stem, causing rapid wear and a tremendous amount of noise.

- Common Mistake: Homeowners often see a "plastic" roller and assume it's the same as nylon. Without ball bearings, a plastic or cheap nylon wheel offers no real acoustic benefit and wears out extremely fast.

Tier 2: Better Rollers (The Common Upgrade)

- Materials: Steel or nylon wheels with 7-10 unsealed ball bearings.

- Lifespan: 5-7 years (approx. 10,000 cycles).

- Description: This is a significant step up. The presence of ball bearings makes operation much smoother and quieter than Tier 1.

- Steel (7-Bearing): Very durable and great for heavy doors, but they are louder than nylon and can rust in humid climates. The metal-on-metal sound of the wheel in the track is still present.

- Nylon (10-Bearing): Noticeably quieter than steel as the nylon wheel dampens vibration in the track. They are the most popular choice for homeowners looking for an effective, affordable upgrade.

- Drawback: The unsealed bearings are vulnerable to dirt and require regular lubrication.

Tier 3: Premium Rollers (The Quiet, Long-Term Solution)

- Materials: High-quality nylon wheels with 11-13 sealed ball bearings.

- Lifespan: 15+ years (rated for 50,000-100,000+ cycles).

- Description: This is the gold standard for residential garage doors. The high ball bearing count ensures the smoothest possible operation, reducing strain on your garage door opener motor. The nylon wheel provides maximum noise dampening, making them whisper-quiet.

- Key Feature: The sealed bearings are the real game-changer. They are permanently lubricated and protected from the elements, making them virtually maintenance-free. If you want the best garage door rollers, this is the tier to aim for.

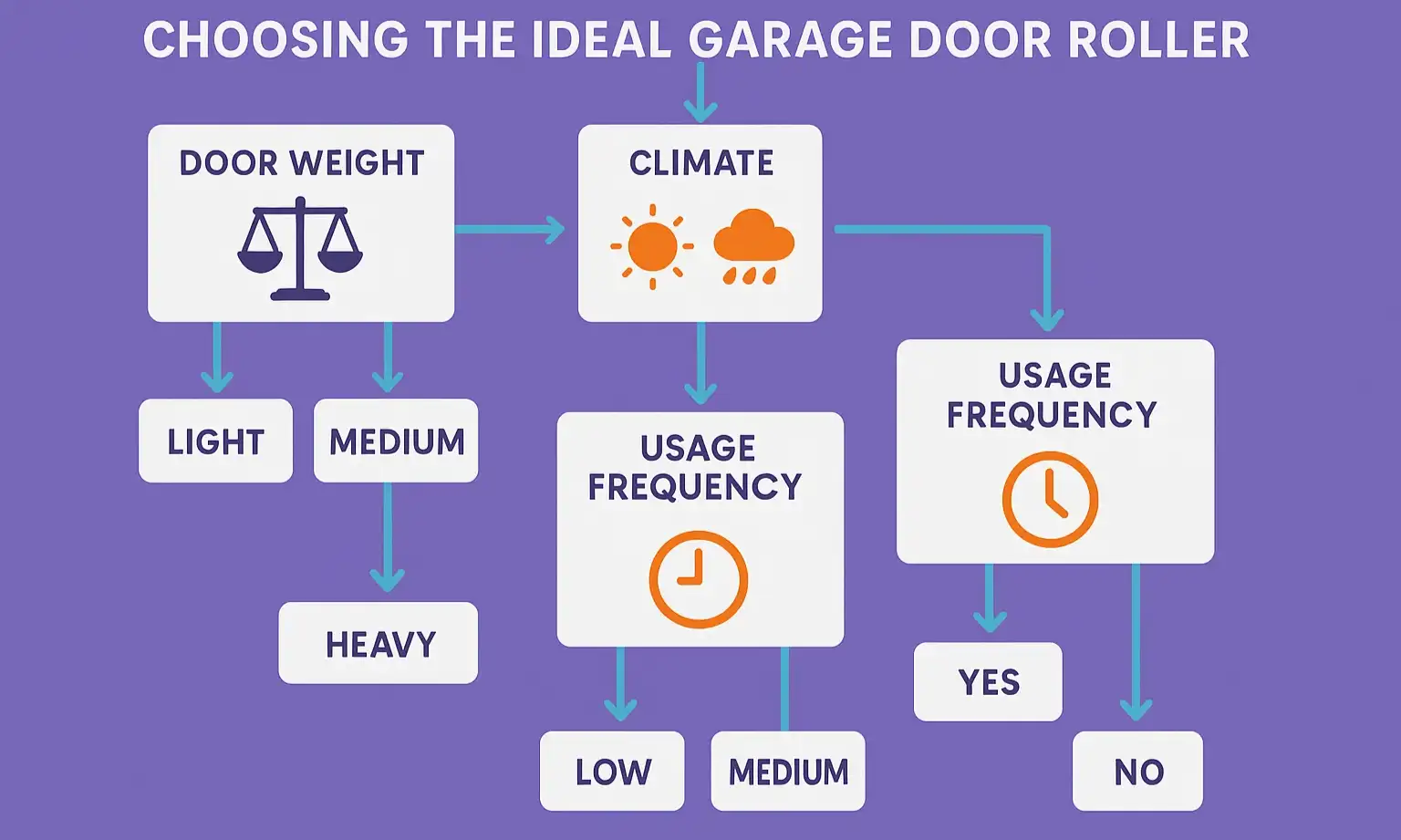

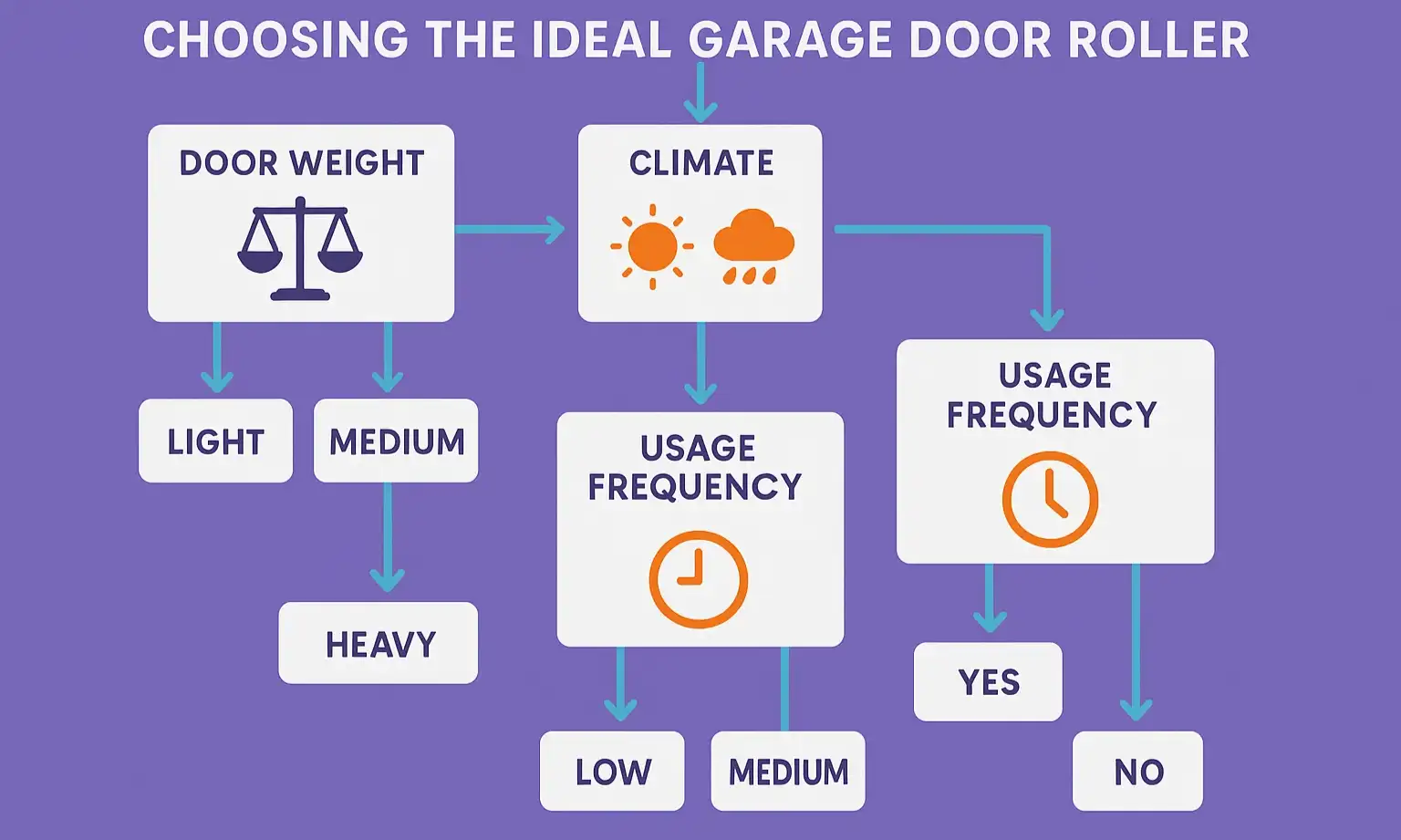

How to Choose the Right Roller for Your Garage Door

Now you can match the right roller tier to your specific needs. It's not just about getting the "best"—it's about getting what's best for your home.

Mastery: Matching the Right Roller to Your Door & Lifestyle

Consider these four factors:

Door Weight:

Standard Steel/Aluminum Doors: Tier 2 or Tier 3 nylon rollers are perfect.

Heavy Wood or Custom Carriage Doors: A heavy-duty Tier 2 steel roller can provide extra durability, but a Tier 3 sealed nylon roller is often still the best choice for its smooth, quiet operation, which reduces long-term strain.

Noise Sensitivity:

Attached Garage (Especially Under a Bedroom): Tier 3 sealed nylon rollers are a must. The noise reduction is dramatic and can significantly improve your quality of life. Even the quietest belt-drive opener will seem loud with cheap rollers. A noisy garage door fix often starts with upgrading the rollers.

Detached Garage: A Tier 2 roller (either steel or nylon) is usually sufficient if noise isn't a primary concern.

Climate and Environment:

Humid/Coastal Areas (e.g., Texas, Florida): Avoid unsealed steel rollers, as they are prone to rust. Tier 2 or Tier 3 nylon rollers are the ideal choice to prevent corrosion.

Dusty/Dry Areas (e.g., Arizona): Sealed bearings (Tier 3) are highly recommended to keep fine dust and sand from getting inside and destroying the bearings.

Usage Frequency:

Standard Use (2-4 times a day): A Tier 2, 10,000-cycle roller will provide years of reliable service.

High-Frequency Use (5+ times a day): Investing in Tier 3 high-cycle rollers (50,000+ cycles) is a smart long-term decision that will prevent you from having to replace them prematurely.

Knowing When It's Time for a Change

Even the best rollers wear out eventually. Keep an eye (and ear) out for these warning signs:

- Increased Noise: Grinding, squeaking, or rumbling sounds that weren't there before.

- Jerky Movement: The door stutters or struggles to move smoothly up and down the track.

- Visible Wear: Cracked wheels, excessive wobbling, or rollers that are falling out of the track.

If you notice any of these signs, it's time to consider a garage door roller replacement. While regular lubrication can help, it won't fix a worn-out, bearing-less roller.

Safety Warning: While some homeowners may be tempted to DIY, replacing garage door rollers can be dangerous, especially the bottom ones. These are under extreme tension from the garage door springs. We strongly recommend contacting a professional for a safe and correct garage door roller installation.

Frequently Asked Questions About Garage Door Rollers

How long should garage door rollers last?

It depends entirely on the quality tier. Basic, no-bearing rollers might only last 1-3 years. A good quality, 10-bearing unsealed nylon roller can last 5-7 years. Premium, 13-bearing sealed nylon rollers can last 15 years or more.

Are nylon garage door rollers really better than steel?

For most residential homes, yes. Premium nylon rollers with sealed ball bearings are significantly quieter, corrosion-resistant, and require less maintenance than their steel counterparts. Steel's main advantage is its raw strength for extremely heavy commercial doors.

What do cycle ratings mean for a homeowner?

One "cycle" is one full opening and closing of the garage door. If you use your door four times a day, that's roughly 1,500 cycles per year. A standard 10,000-cycle roller will last about 6-7 years. A high-cycle roller rated for 50,000 cycles could last over 30 years under the same usage.

How many ball bearings should a good garage door roller have?

More is always better. A good quality roller starts at 7-10 ball bearings. The best residential rollers have 11 to 13 bearings for the smoothest, most durable operation. Anything less, or no bearings at all, is a sign of a low-quality, short-lifespan product.

Do my garage door rollers need lubrication?

If they have unsealed bearings (Tier 2), yes. A light spray of silicone-based lubricant every six months can help flush out debris and keep them running smoothly. If you have sealed bearings (Tier 3), they are permanently lubricated and do not require maintenance. Learn the basics of lubricating garage door rollers to keep your door in top shape.

Your Next Step to a Quieter Garage Door

You're now equipped with the knowledge to look past the simple "steel vs. nylon" debate. You understand that the secret to a quiet, reliable garage door lies in the complete roller system: the material, the ball bearings, and the seals.

By choosing a roller that matches your door, climate, and lifestyle, you're not just buying a replacement part; you're investing in peace, quiet, and long-term performance. Regular garage door maintenance is key, and having the right components makes all the difference.

You may also like